Maximum process reliability

Hildebrand Technology (St. Gallen, Switzerland) has fundamentally revised the iONstream 4.0 discharging system.

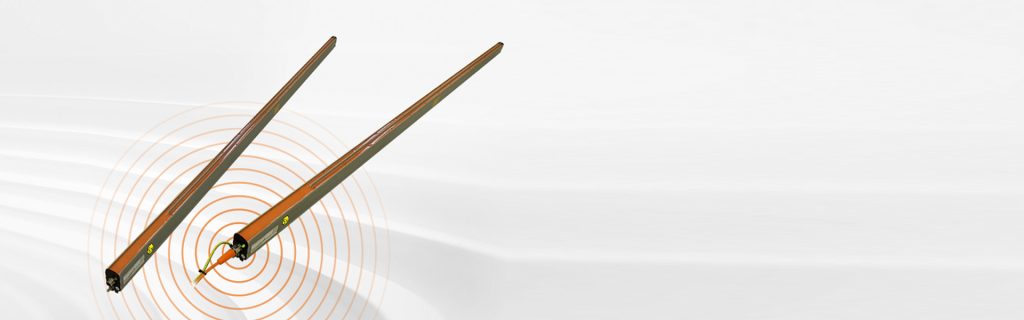

The iONstream 4.0 discharge bars from the Swiss supplier Hildebrand Technology are now equipped with high-performance tungsten electrodes over the entire length. Due to the space-saving integration of the high-voltage generation, the discharge process takes place over the entire length. This improves efficiency and profitability in applications in the processing industry. Thanks to the compact design, engineers have a wide range of options for the flexible placement of the discharge bars in existing and future production plants.

The high-voltage generation integrated in the discharge bars is powered via a 24 volt cable. This eliminates the need to install external voltage generators and at the same time increases operational safety. The discharge bars are made of stable and easy-to-clean glass fibre material. This guarantees a long service life with low maintenance requirements.

New 18kV version and ion detection for even more efficiency

Hildebrand now offers the iONstream discharge system with 18kV voltage in addition to the 6kV and 12kV versions. With higher power, the system reliably discharges all materials, even at the highest speeds and from a great distance. The patented AutoDC technology continuously measures the polarity and flow rate of the ions on the substrate. The integrated automatic adjustment guarantees a continuous and effective positive or negative discharge. In combination with the non-contact Xstream web cleaning system, the smallest particles are efficiently removed up to web speeds of 2500m/min. This measurably improves the quality of the substrates to be processed.

The control system has also been redesigned by Hildebrand Technology and optimized for industry 4.0 applications. The entire system can be controlled via the industrial touch screen “iONControl” with its self-explanatory user interface. Explicit icons, clear statistics and logical menu navigation make operation on the industrial panel easy for every user.

Various networking options for industry 4.0

Hildebrand has made the proven discharging system fit for industry 4.0. The integrated CanBus system enables the customer to connect to existing production and monitoring systems. Theoretically, more than 100 participants and sensors can be easily networked with the system via the interface. All data can be retrieved externally at any time and the user controls the dischar– ging process via an own in–house system. For the user, this improves the traceability of his production processes and the integration into an existing quality management system.

The iONstream 4.0 updates with integrated high voltage make Hildebrand‘s proven discharging system even more compact, efficient and safe. Users will particularly appreciate the discharge over the entire bandwidth, the integration of the voltage generation as well as the durable design. Integration into processing lines becomes easier and economic efficiency during production is improved.

The networking options on Industry 4.0 standard sustainably increase process reliability and quality assurance for the user. The user–friendly operation of the integrated control enables all employees to safely control and adjust the discharging process at any time. The iONstream 4.0 discharging system from Hildebrand Technology, developed and produced in Switzerland, is now available in the new configuration.

From C2 EUROPE 76